|

Descriptions:

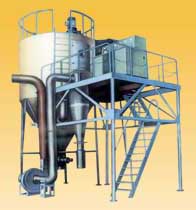

The spray drying is the technology widest used in the liquid technology shaping and in the drying industry, The drying technology is most suitable for producing the poder, particle or block solid products from the materials, such as f solution, emulsion, soliquoid and pumpable paste states. For this reason, when the particle size and distribution of the final products. their residual water contents. the stacking density and the particle shape must meet the precision standard, the spray drying is one of the most desired technologies.

Principle of Work:

After filtering and heating, the air enters into the air distributor at the top of the drier The hot air enters into the drying chamber in the spiral form and uniformly By passing through the high-speed centrifugal spray at the top of the tower, the material liquid will rotate and be sprayed into the extremely fine rnist liquid beads. Through the very short time of contacting the heat air, the materials can be dried

into the finished products, The finished products will be discharged continuously from the bottom of the drying tower and from the whirl sparator. The waste gas will be discharged from blower

Features:

i.At a high speed of drying. after the spraying of the material liquid, the surface area of the material will be increased greatly, In the hot-air flow,95%-98% of water can be evaporated at a moment, The time of completing the drying needs on1y several seconds.

2.This is especially suitable for drying the he8t sensitive materials. lts final products own the good uniforrnity, mobiIity. dissolving capacity, And the final products are high in their purty and good in their quality

3.The produCtion procedures are simple and the operation and control are easy. The liquid with the moisture contents 40-60% (for special materials. The contents rnay reach 90%.) can be dried into the powder or particIe products once a time. After the drying, there is no need for srnashing and sorting, so as to reduce the operation procedures in the production and to enchance the product putity. The

product particIe diamenters. looseness and water contents can be adJusted through changing the operation condition in a certain scope. lt is very convenient to carry out the control and managernent.

Dried Samples:

Foodstuff

Amino acid. V tam n. flavoring. protein. dried milk. pig blood powder.

soy powder. coffee. tea powder. Glucose. potassium sorbate. pectin.

essence. starch. etc,

Ceramics

Aluminum oxide. zirconia. rnagnesium oxide. titanium oxide. sodium

carbonate. china clay. porcelain clay. all kinds of ferrite and metallic

oxide. etc,

Chemical products

dispersed dyestuff. active dyestuff. organic catalyst. white carbon black. yeast. washing powder. potassiurn carbonate. potassium phosphate. inorganic catalySt. all kids of wasted liquid. ofc. |

|